February 29, 2012

Offline

OfflineCJ said

Hello, I have purchased a stainless model 14-2 with serial #SD0190xx. How do I decipher this to know when it was produced? What does the SD stand for? Thanks for any help. CJ

I also have a stainless model 714. The correct model number for the stainless Dan Wesson 357 revolver is 714.

(The 7 in the model number means stainless)

A Model 14-2 would be a blued 357 Dan Wesson with a fixed rear sight. The 714 is the stainless Dan Wesson with a fixed rear sight.

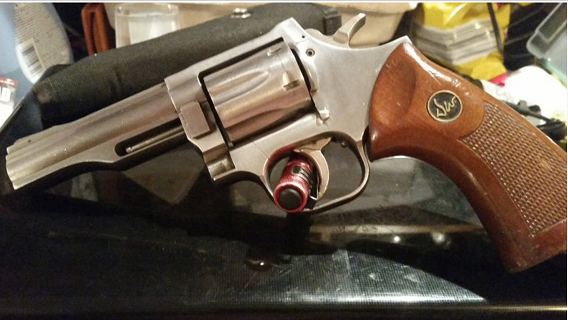

Here's a picture of my 714 with a few mix and match Barrel Assemblies.

The top one with the red sight insert is a 715 B/A.

My 714 Monson made Dan Wesson revolver has a S/ in front of the serial number instead, but I have seen many with the SD prefix like yours has.

Please upload a pic of your new model 714 - We love seeing pictures here on the Dan Wesson forum!

- Bullwolf

February 16, 2016

Offline

OfflineCJ said

I have purchased a stainless model 14-2 with serial #SD0190xx. How do I decipher this to know when it was produced?

The Registry has a 714 with S/N SD008357 that is dated 1983 from the invoice. We don't have factory records, because every time they went bankrupt or sold, the ATF confiscated all their manufacturing records.

So, we can only go by documentation or date of original purchase from members. Not great, but better than nothing.

March 14, 2016

Offline

OfflineBullwolf said

CJ said

Hello, I have purchased a stainless model 14-2 with serial #SD0190xx. How do I decipher this to know when it was produced? What does the SD stand for? Thanks for any help. CJI also have a stainless model 714. The correct model number for the stainless Dan Wesson 357 revolver is 714.

(The 7 in the model number means stainless)

A Model 14-2 would be a blued 357 Dan Wesson with a fixed rear sight. The 714 is the stainless Dan Wesson with a fixed rear sight.

Here's a picture of my 714 with a few mix and match Barrel Assemblies.

The top one with the red sight insert is a 715 B/A.

My 714 Monson made Dan Wesson revolver has a S/ in front of the serial number instead, but I have seen many with the SD prefix like yours has.

Please upload a pic of your new model 714 - We love seeing pictures here on the Dan Wesson forum!

- Bullwolf

Nice 714 Bullwolf! Here's mine. I think it needs some work. It hasn't been well taken care of. I hope to be able to learn from this site how to go through this one and make it right. There is some play in the cylinder rotation at lockup. How much is too much? Is there a bit of movement built into these or should it be pretty tight? CJ

February 29, 2012

Offline

OfflineNot sure just how much cylinder play you should expect in your 714 cylinder at lockup.

Front to back play. (or end shake) All revolvers need to have a little to function, but not an excessive amount of end shake. Most Dan Wesson's don't have problems with excessive end shake, or are just more tolerant of it due to the cylinder alignment ball rear tension lockup.

In this diagram, part numbers:

#19 - Cylinder aligning ball

#20 - Spring (for cylinder aligning ball)

#21 - Aligning ball [tension] screw

The cylinder aligning ball, when adjusted correctly helps keep some forward tension on the cylinder. Of course it can't compensate for a huge amount of end shake either. A problem like that would require the use of a cylinder shim. End shake is easy to measure using a feeler gauge.

Side to side play is more vague... Generally the less you have, the better. If the cylinder notches, or cylinder stop/bolt is badly worn, (Dan Wesson calls the part the cylinder "Bolt") the cylinder may show excess side to side movement.

The Cylinder Stop, or "Bolt" is Part Number #37 in the diagram above.

You can use a range rod to make sure that all the cylinder holes line up while the cylinder is locked up. That will let you know if the cylinder is out of time any. I believe that most revolvers have a little play side to side even when the hammer is cocked. If yours is really loose though, it could be a problem. If you think the side to side play seems excessive, I would consult an expert, like the Dan Wesson factory in N.Y.

My 714 doesn't have that much cylinder side to side play, but if I try to force it while locked up I can make it move some.

If you want to get inside your 714 revolver to see how everything works... Check out the Average Joe tune up.

https://www.danwessonforum.com/forum/reloading/tuning-up-your-15-2-the-average-joe-method/

The Average Joe Tune Up are basically instructions, with pictures that will show you how to take apart and tune up your revolver. Once inside you can look at the cylinder stop up close, and examine the interaction between the hand and the cylinder ratchet, and all the rest of the internals.

More importantly, it also gives you a chance to clean up the gunk and crud that has accumulated over the ages inside your revolver. It's amazing what you will find inside sometimes, from hardened gummed up lithium grease, or just carbon and residue, or it could even be completely dry inside. Often a good tear down, following by a clean and lubing up will makes things work and feel much better.

I'll leave the amount of cylinder rotation when locked up to the experts, or someone else here who can answer the question better than I can.

- Bullwolf

March 14, 2016

Offline

OfflineBullwolf said

Not sure just how much cylinder play you should expect in your 714 cylinder at lockup.Front to back play. (or end shake) All revolvers need to have a little to function, but not an excessive amount of end shake. Most Dan Wesson's don't have problems with excessive end shake, or are just more tolerant of it due to the cylinder alignment ball rear tension lockup.

In this diagram, part numbers:

#19 - Cylinder aligning ball

#20 - Spring (for cylinder aligning ball)

#21 - Aligning ball [tension] screwThe cylinder aligning ball, when adjusted correctly helps keep some forward tension on the cylinder. Of course it can't compensate for a huge amount of end shake either. A problem like that would require the use of a cylinder shim. End shake is easy to measure using a feeler gauge.

Side to side play is more vague... Generally the less you have, the better. If the cylinder notches, or cylinder stop/bolt is badly worn, (Dan Wesson calls the part the cylinder "Bolt") the cylinder may show excess side to side movement.

The Cylinder Stop, or "Bolt" is Part Number #37 in the diagram above.

You can use a range rod to make sure that all the cylinder holes line up while the cylinder is locked up. That will let you know if the cylinder is out of time any. I believe that most revolvers have a little play side to side even when the hammer is cocked. If yours is really loose though, it could be a problem. If you think the side to side play seems excessive, I would consult an expert, like the Dan Wesson factory in N.Y.

My 714 doesn't have that much cylinder side to side play, but if I try to force it while locked up I can make it move some.

If you want to get inside your 714 revolver to see how everything works... Check out the Average Joe tune up.

https://www.danwessonforum.com/forum/reloading/tuning-up-your-15-2-the-average-joe-method/

The Average Joe Tune Up are basically instructions, with pictures that will show you how to take apart and tune up your revolver. Once inside you can look at the cylinder stop up close, and examine the interaction between the hand and the cylinder ratchet, and all the rest of the internals.

More importantly, it also gives you a chance to clean up the gunk and crud that has accumulated over the ages inside your revolver. It's amazing what you will find inside sometimes, from hardened gummed up lithium grease, or just carbon and residue, or it could even be completely dry inside. Often a good tear down, following by a clean and lubing up will makes things work and feel much better.

I'll leave the amount of cylinder rotation when locked up to the experts, or someone else here who can answer the question better than I can.

- Bullwolf

Thanks Bull, great info. I think my problem is with the bolt (#37) and/or it's pivot pin, which doesn't seem to have a part number. I took the side plate off and you are right, it looks horrible in there. I don't think it's ever been apart since it was built, which I'm guessing is about 30 yrs. The bolt seems to be worn at the pivot point allowing it to rock side to side, which in turn allows the cylinder to do the same. Do you know if they make a sleeve for the pivot pin? CJ

February 29, 2012

Offline

OfflineStinger said

Wow, lots of good information, that has nothing to do with production dates. Hope I can find this again when I need it.

If I want to find a thread I have posted in later, I just do a search for my log in name.

Since I am not a paid member of the forum, I don't have access to the Serial Number Registry Database.

I thought you did a pretty good job answering his production date question though Stinger.

Stinger said

CJ said

I have purchased a stainless model 14-2 with serial #SD0190xx. How do I decipher this to know when it was produced?The Registry has a 714 with S/N SD008357 that is dated 1983 from the invoice. We don't have factory records, because every time they went bankrupt or sold, the ATF confiscated all their manufacturing records.

So, we can only go by documentation or date of original purchase from members. Not great, but better than nothing.

If anyone else has more information to add to this thread about production dates, please do so.

- Bullwolf

February 29, 2012

Offline

OfflineCJ said

Thanks Bull, great info. I think my problem is with the bolt (#37) and/or it's pivot pin, which doesn't seem to have a part number. I took the side plate off and you are right, it looks horrible in there. I don't think it's ever been apart since it was built, which I'm guessing is about 30 yrs. The bolt seems to be worn at the pivot point allowing it to rock side to side, which in turn allows the cylinder to do the same. Do you know if they make a sleeve for the pivot pin? CJ

You are most welcome.

Just to be clear we are talking about same parts, check out the images below.

The "Hand" advances the cylinder ratchet. The cylinder "Bolt" or stop, locks the bottom of the cylinder in place through the notches in the cylinder.

A cleaner picture of the cylinder stop "Bolt" with more parts out of the way.

And the "Pivot Point" we are talking about, is the pin that protrudes from the front of the frame which the cylinder stop "Bolt" rides, or pivots on.

I believe the hand, much like the cylinder is a gunsmith fitted part only. Typically Dan Wesson won't sell us parts that requires gunsmith fitting for our own safety (or their liability) and they will only install and fit those parts with the revolver in house. Which is something a bummer for us, because we have to ship stuff to them.

That doesn't mean you can't get another hand or a cylinder, but you may be reduced to only getting a used part. Depending on your skill level, this could be a job for Dan Wesson, and not the Average Joe.

I have never seen a sleeve made for a pivot pin, but I wouldn't put it past a good gunsmith to be able to make one, or to be able to fit a tighter (smaller inside diameter hole) cylinder stop instead.

I think the pivot pin is part of the frame and not removable. The only thing Ive have seen for sale sleeve or shim wise, are trigger shims (a cylinder washer) intended to tighten up end shake from Triggershims.com

Sadly, an end shake washer won't be any help here. I would still try to cleaning everything up, and applying a spot of grease, or a drop of STP to the pivot pin.

A replacement cylinder Bolt (or cylinder stop) part #37 may be available however. A new bolt may help, but only if just the hole is enlarged, instead of the pin that it pivots on.

Before condemning the gun, I would go out and shoot it after a nice clean up. You have not even fired the revolver yet right? Maybe it's not a problem and it's working as intended.

Go out and shoot a box of 38 Special through the old girl, then see what mister target tells you. If you still have concerns after that give Dan Wesson a call to see what they say about it.

Your 714 did not look to have been used very much at all. I can hardly imagine that someone could have worn out the cylinder bolt without a lot more wear and tear showing up on the rest of the gun, other than the mild turn line I see on the cylinder.

Dan Wesson revolvers are a remarkably durable design. They do get dirty over the years though, and often the original owner has never opened one up to clean out the insides.

- Bullwolf

February 16, 2016

Offline

OfflineBullwolf said "Since I am not a paid member of the forum, I don't have access to the Serial Number Registry Database".

Not true my friend .. it's just buried in the FAQ section and if you can't remember where it is, Searches won't find it either.

Here's the link: https://www.danwessonforum.com/wp-content/files/DanWessonSerialNumbers.pdf

March 14, 2016

Offline

OfflineBullwolf said

CJ said

Thanks Bull, great info. I think my problem is with the bolt (#37) and/or it's pivot pin, which doesn't seem to have a part number. I took the side plate off and you are right, it looks horrible in there. I don't think it's ever been apart since it was built, which I'm guessing is about 30 yrs. The bolt seems to be worn at the pivot point allowing it to rock side to side, which in turn allows the cylinder to do the same. Do you know if they make a sleeve for the pivot pin? CJ

You are most welcome.

Just to be clear we are talking about same parts, check out the images below.

The "Hand" advances the cylinder ratchet. The cylinder "Bolt" or stop, locks the bottom of the cylinder in place through the notches in the cylinder.

A cleaner picture of the cylinder stop "Bolt" with more parts out of the way.

And the "Pivot Point" we are talking about, is the pin that protrudes from the front of the frame which the cylinder stop "Bolt" rides, or pivots on.

I believe the hand, much like the cylinder is a gunsmith fitted part only. Typically Dan Wesson won't sell us parts that requires gunsmith fitting for our own safety (or their liability) and they will only install and fit those parts with the revolver in house. Which is something a bummer for us, because we have to ship stuff to them.

That doesn't mean you can't get another hand or a cylinder, but you may be reduced to only getting a used part. Depending on your skill level, this could be a job for Dan Wesson, and not the Average Joe.

I have never seen a sleeve made for a pivot pin, but I wouldn't put it past a good gunsmith to be able to make one, or to be able to fit a tighter (smaller inside diameter hole) cylinder stop instead.

I think the pivot pin is part of the frame and not removable. The only thing Ive have seen for sale sleeve or shim wise, are trigger shims (a cylinder washer) intended to tighten up end shake from Triggershims.com

Sadly, an end shake washer won't be any help here. I would still try to cleaning everything up, and applying a spot of grease, or a drop of STP to the pivot pin.

A replacement cylinder Bolt (or cylinder stop) part #37 may be available however. A new bolt may help, but only if just the hole is enlarged, instead of the pin that it pivots on.

Before condemning the gun, I would go out and shoot it after a nice clean up. You have not even fired the revolver yet right? Maybe it's not a problem and it's working as intended.

Go out and shoot a box of 38 Special through the old girl, then see what mister target tells you. If you still have concerns after that give Dan Wesson a call to see what they say about it.

Your 714 did not look to have been used very much at all. I can hardly imagine that someone could have worn out the cylinder bolt without a lot more wear and tear showing up on the rest of the gun, other than the mild turn line I see on the cylinder.

Dan Wesson revolvers are a remarkably durable design. They do get dirty over the years though, and often the original owner has never opened one up to clean out the insides.

- Bullwolf

Thanks again Bullwolf, I took it all apart after reading the average joe post. I got everything cleaned up. I'll take it out and shoot some target ammo. I'll let you know how it goes. CJ

1 Guest(s)

Register

Register Log In

Log In Home

Home