January 5, 2015

Offline

OfflineI recently acquired what I would consider a nice 'shooter' with 6in bbl at a comfortable price. In learning a bit on how to evaluate a revolver I do notice that I have perhaps a bit of fore and aft travel if I push or pull the cylinder. Obviously the barrel will stop the fore travel based on how tight I set the cone gap which is currently about 4.5-5 thousands.

So my question is before I begin to purchase any additional barrels how, who and where can I have this situation corrected? And by chance is there a set amount of tolerance for this travel to use to tell me how extreme mine is? The gun is shooting nicely and I am a low volume shooter most often going to shoot 38spl target loads and infrequent magnum rounds.

thanks

Karl

Dans Club

April 18, 2014

Offline

OfflineDepending on how much play your talking about. If bad enough you SHOULD send it to Dan Wesson Norwich. I am not sure what the specs are. I would think if the gap is set good for the gun and accuracy is there, may be ok. I would venture that rearward travel should be no more than .002-.003. that is a guess..

Oath Keeper #021479 NRA #206814004

Member AAGSR Member AGA #83120600233

"To preserve liberty, it is essential that the whole body of the people always possess arms and be taught alike, especially when young, how to use them."

Richard Henry Lee

American Statesman, 1788

Supporter

Range Officer

Moderators

DWF Supporters

Dans Club

December 4, 2011

Offline

OfflineYou may just need a new spring in the alignment ball. End shake shims are also available. I don't know the spec so lets see if anyone else does.

Anything worth doing is worth doing well.

My father

If a man designed it, and a man built it, then a man can fix it.

My grandfather

December 19, 2014

Offline

OfflineTwo things:

1) You do not use the cone gap to alleviate cylinder fore-aft travel (in any revolver).

2) Because of 1), you need to fix or adjust something else. Possibilities are a worn or ill-seated cylinder bushing (in the front of the cylinder); a bad alignment ball system (spring or ball itself) or ill-adjusted ball system; worn or ill-seated ejector (star). There is also the possibility that there is a crane issue (wear on either top or bottom or both).

Dans Club

April 18, 2014

Offline

OfflineI found an article on checking out the revolver. I am going to upload it in the reloading, gunsmithing and grip making forum.

Oath Keeper #021479 NRA #206814004

Member AAGSR Member AGA #83120600233

"To preserve liberty, it is essential that the whole body of the people always possess arms and be taught alike, especially when young, how to use them."

Richard Henry Lee

American Statesman, 1788

January 5, 2015

Offline

OfflineOK thanks for suggestions and info. Closer evaluation shows there is about 10-12 thousands of travel to the rear. There doesn't seem to be any side to side play at the rear where the spring/ball engages and there is resistance on the ball from the spring.

Where the ejector rod passes through a small busing in the swing-out pivot arm there is a great deal of slop. I apologize as I likely don't have the correct terminology of parts correct yet:) learning is fun LOL. I don't quite understand what determines how much travel to the rear there will be, is there an internal stop somewhere on the ejector rod where it passes through the swing out arm? I would assume the rear spring/ball tension would not be alone enough to stop the rear travel of the cylinder? I also see some blueing wear on the very outside end of the rear cylinder perimeter as if it has dragged somewhere during rotation however it is not dragging or binding when the cylinder is fully closed.

Image: If it helps mine is a six digit serial number starting 300...

Any more thoughts..........or guidance?

Thanks.....

Karl

Dans Club

April 18, 2014

Offline

OfflineKarl in what you are describing there is considerable wear. My suggestion would be to contact Keith at DW Norwich. One of the brothers here probably has his info. That much wear should be corrected by a professional.

Oath Keeper #021479 NRA #206814004

Member AAGSR Member AGA #83120600233

"To preserve liberty, it is essential that the whole body of the people always possess arms and be taught alike, especially when young, how to use them."

Richard Henry Lee

American Statesman, 1788

Range Officer

Range Officers

Dans Club

February 28, 2009

Offline

OfflineHere's his info:

Keith Lawton keith@cz-usa.com

Good guy. Very busy but will attend to your problem as soon as he can.

-Mike

December 19, 2014

Offline

OfflineI'll second (or triple) sending this to DW. I'll try and answer your question wrt what limits the fore-aft travel of the cylinder. (If this is wrong, hopefully someone like Eric will correct).

In your pic, the red circle around that dimple on the frame is what keeps the cylinder from traveling aft when the cylinder is opened.

When the cylinder is closed, the tension ball/spring are what keeps the cylinder "pushed" forward. Any rearward travel is limited by the back of the frame (or the compressed spring/ball interference with the detent in the ejector star). As you can see in the pics below (from a disassembly tutorial) there is no internal stop to keep the cylinder from sliding off the crane, other than the knob on the end of the ejector rod (that's why the rod needs to unscrewed in order to completely separate it from the crane - BUT on my early Model 15, the ejector rod doesn't have that knob on the end so it will slide through the crane barrel without needing to be unscrewed).

So I think when the gun is fired, any extension left in the tension ball spring will most likely compress until the cylinder stops at the back of the frame (actually the ball bottoms out in the ejector star). Again, I think this is the case based on what I see in my gun. This makes me wonder about the cylinder-bore gap, set when the cylinder is pushed forward, then when it's fired it increases by some about (e.g. from 0.006 to 0.008 or more)??? Maybe someone smarter with a lot more smitty experience can chime in. Hope that helps (or at least doesn't hurt LOL). Paul

A little Dan Wesson barrel gap info. The gap should be set at .006 on the proudest chamber. That means that every chamber should be checked with the .006 shim. Most of us use automobile gap shims of different sizes. The gap may vary on the 6 chambers. I personally have found little variance but even a difference of .002 or .oo3 can make a difference. When the cylinder heats up and expands or powder builds up on the front of the cylinder the gap can narrow and the cylinder can bind. Take the tool with you when you shoot and adjust it if needed. The factory spec is .006 on Dans and most other revolvers to give room for the expansion of the cylinder and powder residue build up. The gap in Dans can be reduced to prevent propellant from blowing out and increase muzzle velocity if the cylinder face is perpendicular. When setting the gap the shim should be able to slid easily in and out of the gap. It is natural that the cylinder be able to be pushed to the rear but do not do this when setting the gap or the gap will be too tight. End shake is when the cylinder can move front to back when the gun is in lockup. Shims can fix the play as can a new bushing. First make sure the gap is set correctly. If you have no problem when shooting and the the cylinder is not now rubbing on the frame your problem may have been fixed previously. Second step would be to change the small springs and parts. The official barrel tool, whether it is plastic or metal is all you need to disassemble and fix almost anything on your gun. Refer to the "Average Joe Tuneup" pinned to the top of small frame revolvers and just go as far as you feel comfortable. Most of us get great joy from cleaning tuning and fixing our guns. Karl Lewis, the guns inventor designed it to not need a gunsmith for most things that other brands either require the factory or a smith. A cleaning and small part replacement are all that is usually needed to make a gun work like new. If you need help let us know and bunches of folk will chime in. Before long some REALLY knowledgeable folks will undoubtedly chime in.

January 5, 2015

Offline

OfflineI wish to thank everyone for the great information. I will digest it and also speak to DW repair for more insight if I have them service it. I think it is the beginnings of a fun little project of love for the gun

The circled 'stop' that is shown makes sense, I believe that perhaps the forward bushing looseness where the ejector rod passes through is allowing the rear of the cylinder to 'drop' a bit when it is being guided back into the frame thus causing the wear ring on back of cylinder. Further investigation and some disassembly is in order.

I'm still all ears for any other info that anyone cares to share.

Thanks all...

Karl

December 19, 2014

Offline

OfflineHey Karl - I've been scouring the internet and old mags and rags about endshake, cuz the design of the DW's seems to be different enough from other revolvers that endshake should be kind of non-event (typically). I say that because the frame stretching and ejector star banging that is typical in rear-crane lockups does not necessarily exist in DWs (because of the tension ball/spring unit). At least this is my opinion. Here's what someone else said ref endshake and DWs:

"(Interestingly, the Dan Wesson guns are very robust in terms of their endshake handing; the spring-loading bearing detent at the rear of the frame locates the cylinder at the forward-most position every time, and also serves to absorb a bit of the recoil force of the cylinder.)"

I think your right on pursuing the cylinder bushing, and also maybe the ejector rod itself (is it straight and no excess wear on it). Make sure you check the tension ball/spring pressure in that it's strong, but not so strong to keep the cylinder from closing without a lot of force.

I'd like to tighten up the crane lock on my early model 15, it adds the slightest side-to-side motion in the cylinder, not much now, but... Not sure where to start on that.

Good luck. Paul

January 5, 2015

Offline

OfflineHey Paul you may be on to something here!....(Hey Karl – I’ve been scouring the internet............ ) What you are saying makes sense in the fact that the ball and spring is a tensioner for the cylinder. I'm not so sure I am correct in my observations of what I am experiencing and perhaps the only issue that does need attention is the ejector rod bushing area?

I have contact info for Bob Davis at Dan Wesson service in NY and I think I will give him a call and discuss more accurately what I have to see if sending it in is necessary or not. Thanks for making me think more about it, I don't have any other DW to compare it too, perhaps what I really need is another one

Your pictorial description as well as reasoning now makes good sense to me. Interesting is what you are saying about the gap to cone also. I will likely call and speak to Bob at DW and carefully reason out what I am seeing and listen to what he says to check before I send it in, approx. estimate from him at this point was $160 to $180. I'm fine with that if it has to be done as I got it for a good bargain IMO. I'll update this thread when I learn more about the fore/aft travel of a DW cylinder.

I'm glad I joined in to this forum, thanks to all again..

Karl

January 5, 2015

Offline

OfflineOK folks I ordered from DW a complete spring kit for my revolver for an internal rebuild, also ordered an ejector rod bushing because mine is well worn. I also ordered a set of Wolff springs to tune up the action a bit. Because of my concern on the amount of 'endshake' I ordered cylinder shims from Triggershims.com and I must say they are the nicest most willing to help folks you could possibly do internet business with!

I was going to send the gun in, Bob Collins at Dan Wesson in NY was very helpful as was Shawn in the parts department to get my list of needs together. So I will cautiously learn how to disassemble and reassemble my DW revolver and will be anxious to see how the Wolff springs work out to enhance trigger action.

I will likely update this thread with some internal images and comment on my experience to share with others. Meanwhile while waiting for components to arrive I can do some reloading!

January 5, 2015

Offline

OfflineUpdate with images coming: I received the end shake shims from Triggershims.com in .002, .003, .004 thickness and they measured perfectly with my calipers so I can fine tune some travel out of the cylinder. On my cylinder the front protrusion is shown in some YouTube videos as being a removable bushing, mine is a fixed bushing to the cylinder?

The Wolff springs have arrived so I will experiment with hammer and return springs both. I use CCI primers in my reloads so we will see if the reduced spring causes any light strikes or no fires and if so I will put stock spring back in. I also received the 'spring kit' from DW so I have a spare set of factory springs if needed, or if one shows up missing:)

One step further I ordered some Arkansas stones to possibly polish up any mating surfaces, not remove material but polish surfaces. I would eventually like to learn and do some trigger job work on my other revolvers so the stones will come in handy. They are not cheap but I found a reliable source for stones if anyone needs them at Danswhetstone.com His knowledge of the stones is impressive and I don't have to worry about getting something other than what I expect.

The removal of the side plate in disassembly was easy, the screws backed out easy and I tapped the handle several times with a nylon mallet until I heard the plate rattle loose. Inside the gun is surprisingly clean and relatively simple in design. I am enjoying the mechanics of the gun internally and am looking forward to smoothing out a few surfaces to reduce friction and give a nice double action trigger pull as well as SA release.

I'll add a few images later...........................Stay tuned!

Adding a few pics for reference. If anyone notices something please make me aware of it. Also I hope these pics might help someone else for reference at sometime too

Internals......I have no idea the history of this gun, it is a six digit serial number made in Monson MA

Pic#1

The insides looked better than I thought they would. I will give a good clean up, and touch up any surfaces with Arkansas stones that show friction surfaces to smooth out carefully.

Pic #2 lower area of trigger and crane area

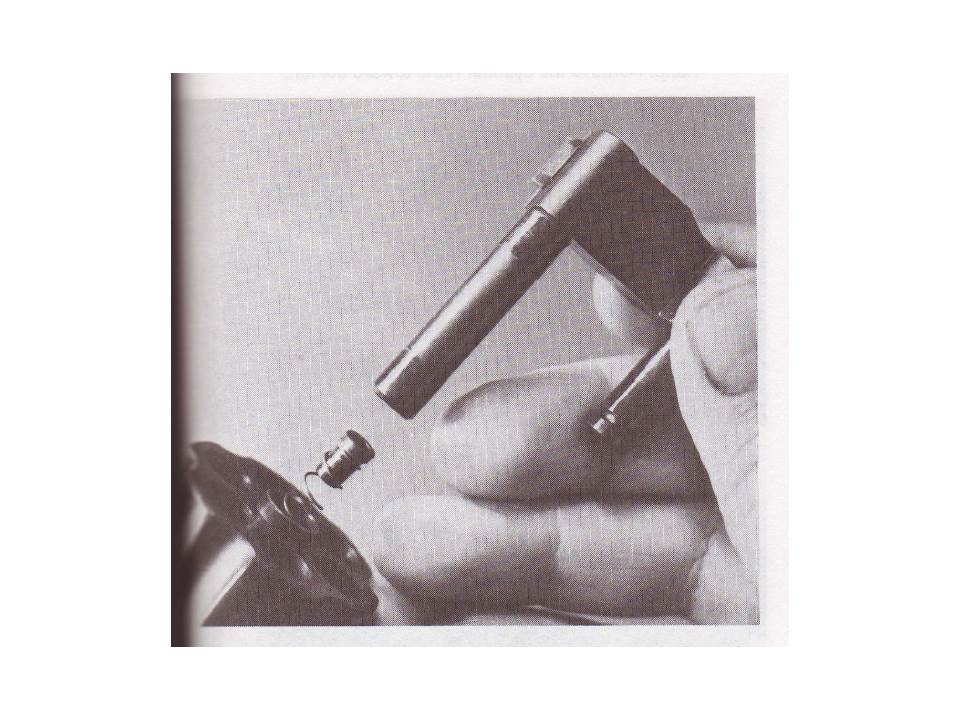

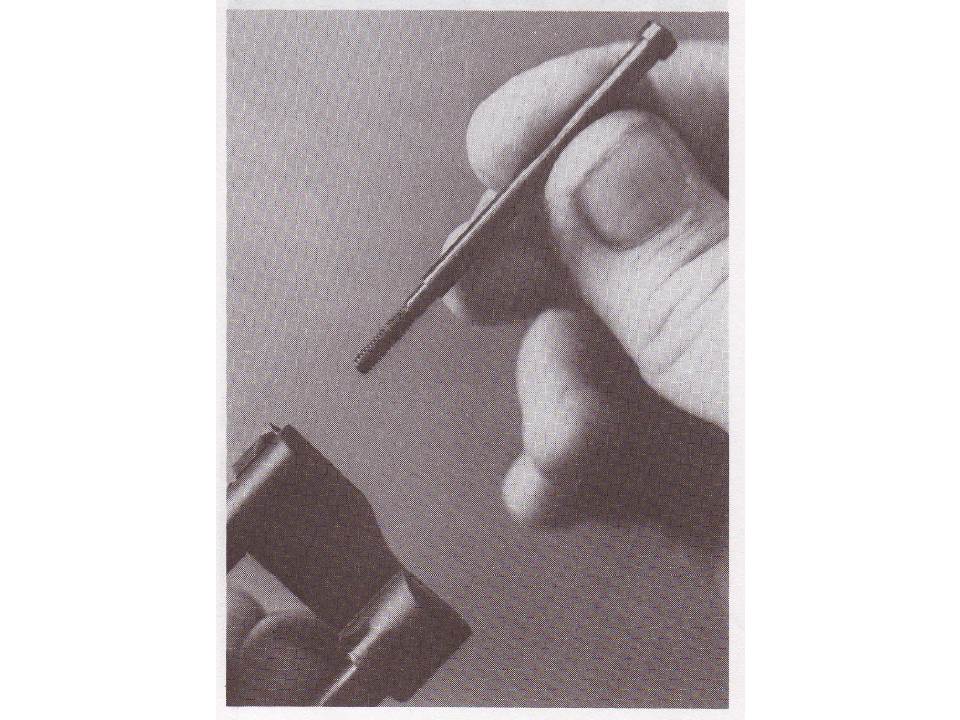

Pic #3 The easy way to pull the Crane lock clip..........with a magnet:)

Pic #4 reference to the TriggerShim company if you need any shims and they measured spot on! Great folks to deal with too

More to come as the project progresses. I ordered a Lyman trigger pull gage so I will get a before and after on trigger pull readings. I have the Wolff springs to go in and some Arkansas stones coming to polish mating surfaces with. Yes you might say I'm hooked

More coming as project progresses..........

Karl

January 5, 2015

Offline

OfflineUpdate to this project:

Complete disassembly went well, this is a very basic revolver internally and is easy to service.

I removed all components and cautiously polished all surfaces that made contact, sear, hammer and all areas that showed a bit of black being removed from the metal components.

I could feel the smoothness in the action after the polishing, I would consider it a benefit for sure. I installed the Wolff Spring kit and honestly did not see any great deal of improvement. This could be possibly because I am unsure of the Hammer spring that came out of the gun being an original DW spring. Wolff supplied two Hammer springs in their kit, one at 7.5lb and one at 8lb with them stating the factory was approx. 9lbs. I installed the 7.5lb spring and the reduced power Trigger spring. I will warn you that the lighter Trigger spring can easily be distorted from its original shape if not carefully manipulated when intstalled, I put a bend in mine that rendered it useless so I put the factory back in so I could go to test fire.

Test firing proved out that the 7.5lb Hammer Spring was just a bit too light at times for the CCI primers as I experienced enough misfires/light strikes in DA. Each round fired fine in SA mode that had previously misfired. When I got home I installed the 8lb Hammer Spring which I will test for 100% function.

All in all I would say that the Wolff Springs were no significant benefit to the overall DA function of my gun though I plan to leave them in. Perhaps my guns original springs that possibly could be over 30yrs old had worn in nicely:) I have ordered a Power Custom 1 stoning fixture with jigs to learn to do more trigger/sear work. They offer individual jigs for most gun models to properly index hammer and sear for accurate stoning, I hope to find out if there is one that can double up for maybe more work on mine to get a little lighter SA trigger pull.

There is something very rewarding about doing your own action work for me as there is about doing your own reloading. I would like to continue to understand more about trigger work and action work and apply what I learn. Now I need to buy or find more 'patients' to practice on!

If anyone here has insight on refining the DW trigger system please let me know. I tested a friends Ruger GP100 that he paid to have a trigger job done on and found his SA release was an impressive just shy of 3lbs and his DA was in the 8lb range. Currently my DW is around 10lb DA and about 5lb SA.............don't get me wrong, it is a nice feel overall but I am interested in taking it further without losing reliability on striking the hard CCI primers, if it fires a CCI primer then I know it will fire all others.

I hope this information is helpful for someone else. I also learned a great deal about the internals and functions they perform, I also experienced a few set backs that made me realize how one could have some glitches in their action feel. If you have a question you think I could help with or share my experience please let me know.

Karl

January 5, 2015

Offline

OfflineOh, and by the way, I added .003 endshake shim on my cylinder and this reduced the amount of rear travel I had on the cylinder. Too thick of shim would cause the cylinder to bind in rotation when dummy test cartridges were dropped in. The nice thing about the DW revolver is that you can compensate for the forcing cone gap with the barrel being adjustable, I set mine up at .004 gap.

Karl

Dans Club

April 18, 2014

Offline

OfflineGood update Karl. I think it will be beneficial to some here. Thank you.

Oath Keeper #021479 NRA #206814004

Member AAGSR Member AGA #83120600233

"To preserve liberty, it is essential that the whole body of the people always possess arms and be taught alike, especially when young, how to use them."

Richard Henry Lee

American Statesman, 1788

That was a great effort Karl. Well written also. I wish I was as organized as you. You will find that the more you use your Dan the smoother it will be. One of the old timers said to just even the contact surfaces. I would be careful with the jigs and stoning. Please try another Wolff trigger spring. The difference is very noticeable. I wood be interested in your opinion. By now you should be planning your next Dan purchase. I believe you have DWAS already.

1 Guest(s)

Register

Register Log In

Log In Home

Home