Dans Club

October 26, 2008

Offline

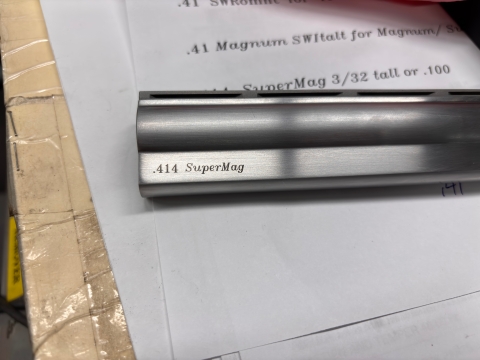

OfflineLike many others on the forum I have wanted a 414 Supermag for a long time. Made a few attempts at getting one and either went beyond my funds at the time or I was 2nd in line. Decided for the time being I would at least be able to see if I liked it without dropping big $ by converting a surplus 740 to 414.

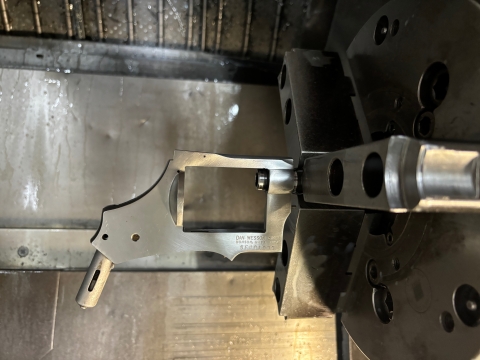

Started by convincing Dan Wesson in Norwich (not easy btw) to sell me a cylinder. In the process they informed me that they had no more large frame extractors for 357 or 41. I placed a want ad on here and a couple other places along with looking at the normal parts places and ebay with no success. Decided that the only direction I could take would be to make one. Took a 44 that I did have back engineered it to the best of my ability confirmed everything on a CNC CMM and modified the cutouts for 41. Since my day job is to program CNC lathes, mills and a Multus along with some solid modeling when engineering is backed up I drew up a model and made a print. Then programmed the front side (the part the hand actually rotates) and managed to slip it through the shop leaving the back star shaped slots to do manually. I did that since I was trying to be quick and not tie up a machine for a long time (not planning on making a bunch). Sent them out to heat treat, made a fixture for a manual mill, machined the back shape, made the hex rod the extractor actually is assembled on and fit it all together. The barrel was a 10” DW 41 barrel I got from rwsem that was cut down and rethreaded for the frame end 11/16-32 and the nut end 21/32-40. Cut the forcing and threw my normal crown on it. Then polished everything up which took a while DW was not great with their as machined finish. Took it out for it’s test fire yesterday and seemed to shoot good everything worked as it should. I think it made me want a real one even more now………

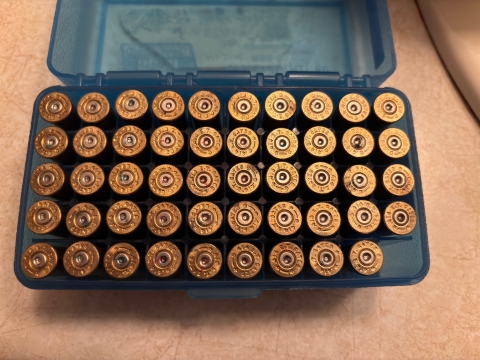

Hopefully Starline will make some more brass soon.

Hopefully Starline will make some more brass soon.

Supporter

DWF Supporters

February 16, 2013

Offline

OfflineSupporter

Moderators

Dans Club

February 22, 2009

Offline

OfflineTechnically, the glass is always full; half liquid, half air....

Dans Club

October 26, 2008

Offline

Offlinerwsem said

Nice job on the extractor- I was lucky enough to source the extractor with the cylinder when I did the conversion of my "extra" 740. I cerakoted the cylinder black as a visual clue to check the bore on the barrel. Thanks for the forcing cone cutter!

Is that an EWK shroud with the picatinny machined top? I didn’t know he did a run of those for the large/supermag frame! No problem on the cutter like I said just pass the karma along to someone else sometime.

Supporter

Moderators

January 24, 2009

Offline

Offline

DWF Supporters

February 24, 2013

Offline

OfflineSupporter

Moderators

Dans Club

February 22, 2009

Offline

Offlinesuperdan said Is that an EWK shroud with the picatinny machined top? I didn’t know he did a run of those for the large/supermag frame! No problem on the cutter like I said just pass the karma along to someone else sometime.

It is indeed an EWK railed shroud. Made a ton of sense to me when he made them and for a long time all I did was hunt with handguns. Karma never stops with me... that's bad juju

Technically, the glass is always full; half liquid, half air....

DWF Supporters

February 24, 2013

Offline

Offline

DWF Supporters

February 24, 2013

Offline

OfflineRange Officer

Range Officers

Dans Club

February 9, 2009

Offline

Offline1 Guest(s)

Register

Register Log In

Log In Home

Home